IRAETA Rotary Kiln Tyres

The rotary kiln tyre, also known as the rolling ring (support ring), is used to transfer all the gravity of the cylinder to the supporting roller, and to make the cylinder rotate smoothly on the supporting roller. It is a component of the supporting device of the rotary kiln and bears part of the weight of the kiln body, plays an important role in the smooth operation of the kiln body. Rotary kiln tyres are subject to contact stress and bending stress during the rolling process, and the surface is prone to cracking and peeling. The damage is relatively large. In addition, the rotary kiln tyre is operated under high temperature, high pressure and harsh environment for a long time. The tyre needs to have sufficient compression resistance and wear resistance.

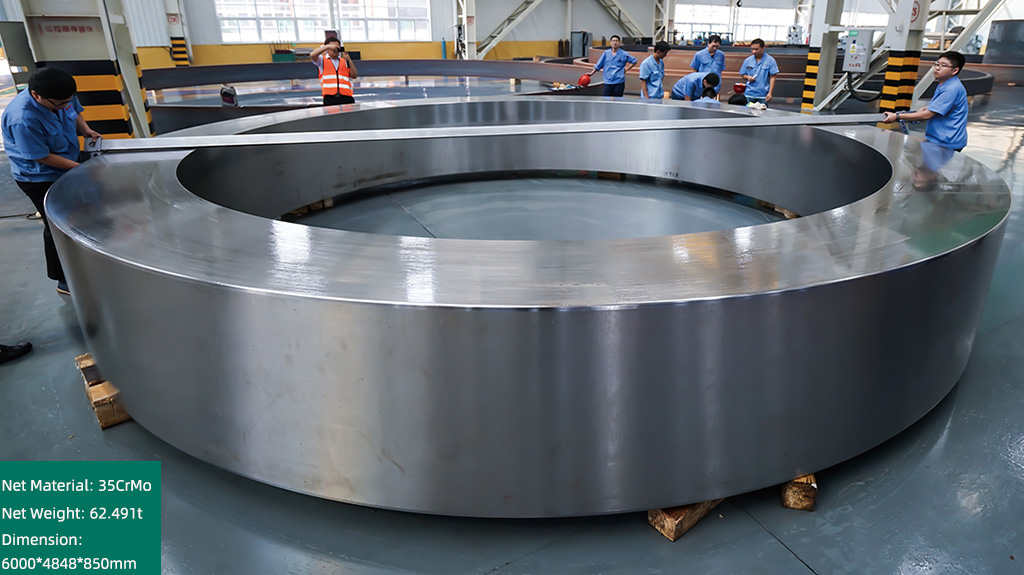

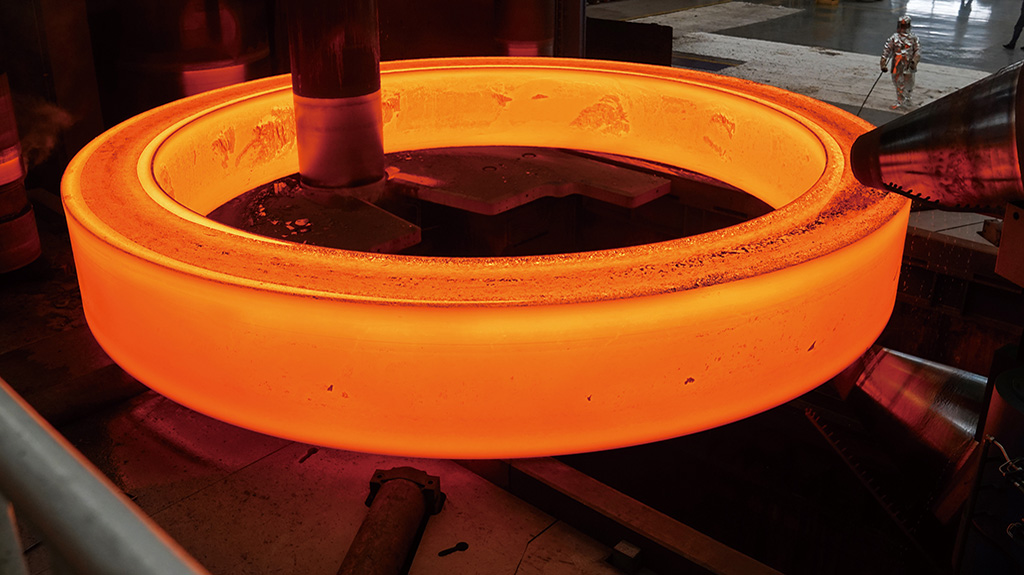

IRAETA adopts customized raw materials and radial-axial rolling technology to make the tyre near-net-shape. After rolling, the tyre has been dense and even, and the surface becomes consistent and smooth, which greatly reduces processing time, achieve green forging, at the same time, faster delivery. Therefore, the forged tyres have better performance and longer service life. At the same time, we have successively provided large rotary kiln tyres forging products with a diameter of more than 7000mm to well-known global companies such as ThyssenKrupp and Cemex.

Parameter

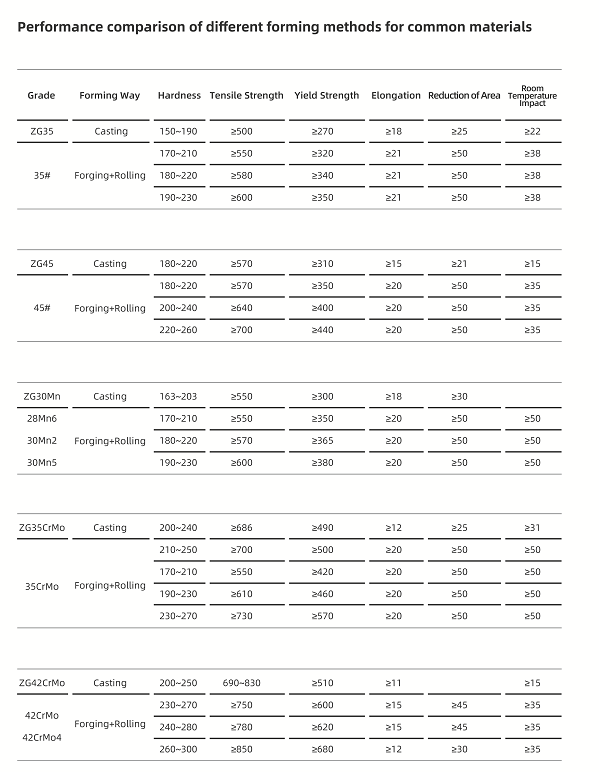

Material

Size Range

Piece Weight Range

Heat Treatment

Testing

Equipment Capacity