Introduction to Oversized Seamless Rolled Rings

IWith a total investment of RMB 600 million and an area of 80,000 square meters, Iraeta Nuclear Duty Division relies on the "Academician Li YiYi Workstation" set up by the Institute of Metals of the Chinese Academy of Sciences to research, develop and manufacture large-scale forgings made of integral high-alloy steel and various non-ferrous metals.

We use the industry's advanced CNC, intelligent forging, heat treatment, machining equipment, including 13,500 tons of hydraulic presses, hearth width of 8 meters trolley-type heating furnace, internal diameter of 7.5 meters folio-type heat treatment furnace, internal diameter of 17.5 meters pit-type heat treatment furnace, diameter of 19 meters, depth of 5 meters quenching tank, cutting diameter of 16 meters of the large-scale vertical CNC lathe, including the introduction of the RAW2500/1250 from the German SMS. Including the RAW2500/1250-16000/3000 ring and cylinder rolling machine imported from Simak, Germany.

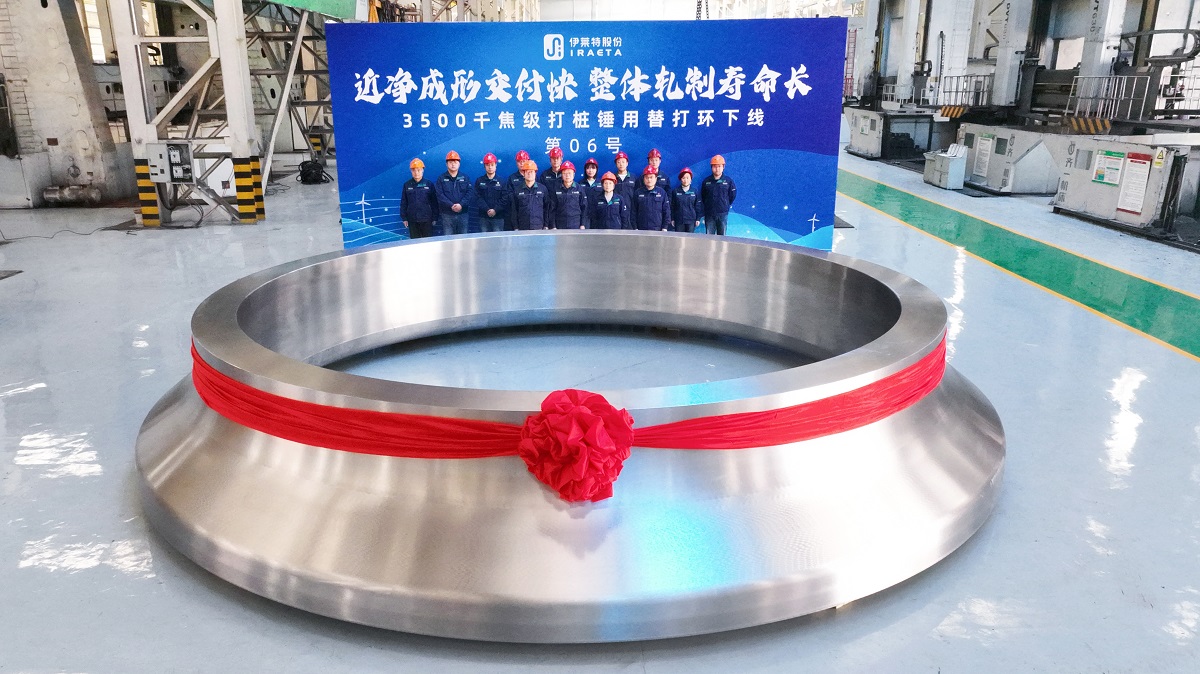

Main Products:Outer diameter of 16 meters, height of 3 meters, single weight of 200 tons of all kinds of discs, rings, cylinders, large modules, pipe plates, shaped forgings.

Application Areas:Offshore wind power, nuclear power and hydropower, advanced refining, equipment manufacturing, aerospace, and mold manufacturing.

Introduction of main equipment

16 meters ring and cylinder rolling machine

Germany Simak ring rolling cylinder rolling machine, the maximum rolling diameter of 16 meters, height of 3 meters, a single weight of 200 tons, radial rolling force of 2,500 tons, axial rolling force of 1,250 tons. The equipment has excellent performance and high stability, and can be rolled and molded into various kinds of oversized cylinders, rings and other forgings.

16m rolling diameter, 3m rolling height, 200 tons single weight.

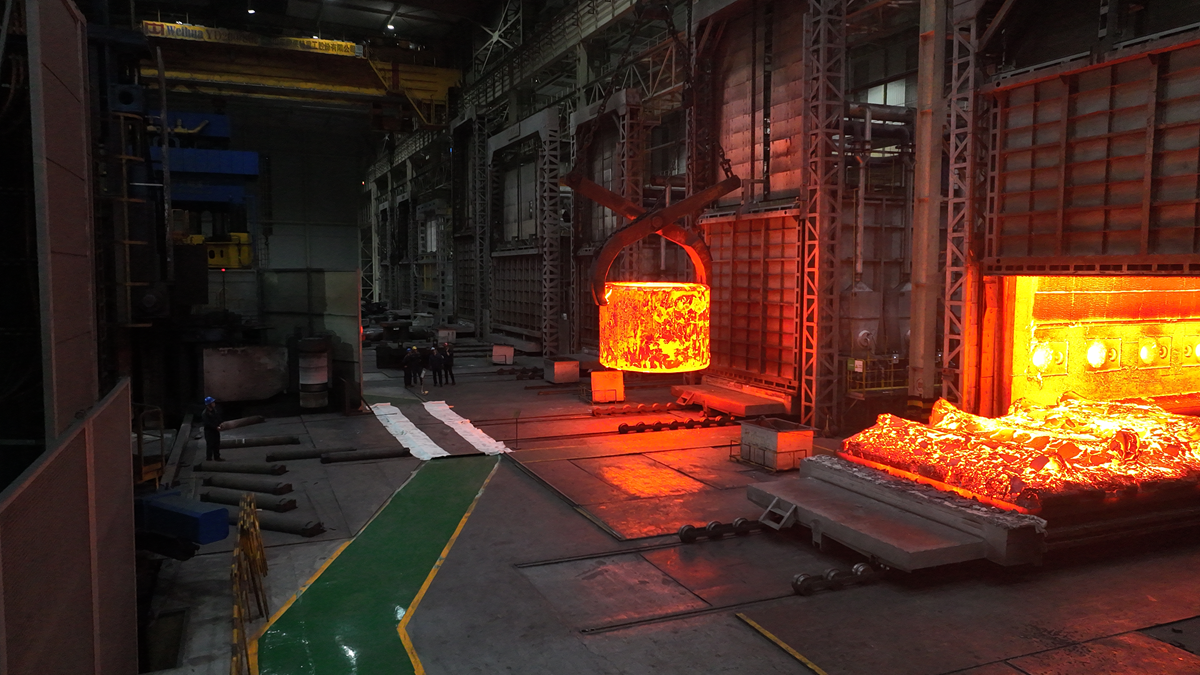

13,500 tons of presses

Tianjin Tianforging 13,500-ton press, with a total height of 18.5 meters, a moving table with a width of 5 meters and a stroke of 10 meters, a movable crossbeam with a stroke of 3.5 meters and a headroom of 7 meters, the maximum pressure can be up to 13,500 tons, equipped with a German Rexroth hydraulic system and a Siemens electronic control system, which can realize high-precision control of large forgings.

Parameter

Material

Diameter range

Length/height range

Piece Weight Range

Heat Treatment

Testing

Processing